How UAE’s 50°C Summers Destroy Motor Insulation And How Rewinding Saves It

Summer in the UAE will test the strength of any technology. The temperature rises to 50°C, humidity does not let go even at night, and dust from the desert penetrates into every crevice. Electric motors are the first to suffer. The stator and rotor windings overheat, the insulation collapses, and short circuits begin. The statistics speak for themselves: half of all failures are due to electrical causes, of which 38% are damage to the windings, 12% are rotor failures.

Why Rewinding Becomes Essential

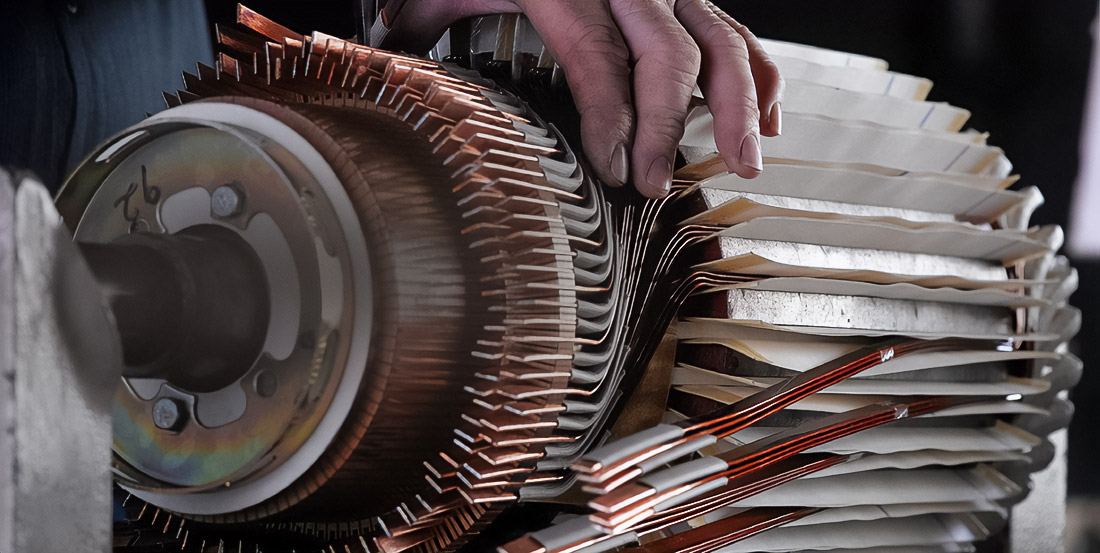

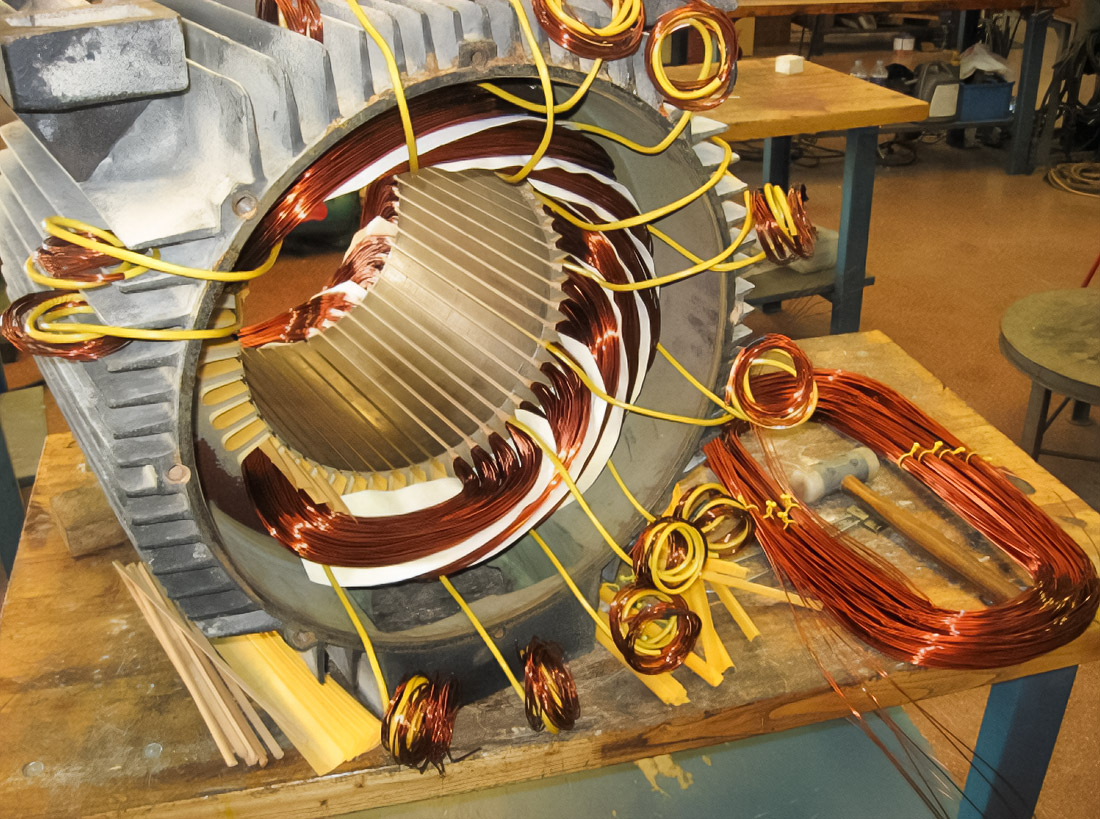

Rewinding in such conditions becomes not just a repair, but a full-fledged way to prolong the life of the equipment. The essence of the process is the replacement of old coils with new ones, the use of improved insulation, varnishing and heat treatment. Everything ends with a series of tests: measuring resistance, surge tests, checking the polarization index. These steps ensure that the engine will operate at rated power again and within the framework of IEC, IEEE and EASA standards.

The key problem is overheating. Class F allows 155°C, but the acceptable limit for normal operation is 145°C. And although the case seems cooler, the difference between the surface and the inner windings is about 30°C. As a result, the motor can “deceive” the operator, but destruction is already underway inside. Every additional 10°C reduces the insulation life by half. For example, at 155 °C, it retains half its strength for 20,000 hours, at 165 °C only 10,000, and at 175 °C less than a year. If the temperature is lowered to 135 ° C, the duration increases to 80 thousand hours.

Rewinding helps to use higher grade insulation, such as H, which can withstand heavy loads and slows down the aging of materials. This is especially important for engines operating around the clock in Dubai’s industrial zones, Sharjah’s seaports, and Abu Dhabi’s oil facilities. Here, moisture and sand increase damage, accelerating short circuits.

Economic and Technical Advantages

The financial benefits are obvious. Rewinding is 30-50% cheaper compared to buying a new engine. And the recovery time is only 24-72 hours. In an environment where idle equipment costs more than the equipment itself, this is a critical argument.

But rewinding has another advantage: the ability to upgrade. Windings can be strengthened, higher-grade insulation added, voltage regulation in generators improved, or speed control accuracy restored in DC machines.

Diagnosis is a mandatory step. First, the engine is inspected, the shaft rotation is checked, and the resistance is measured. The insulation resistance must be at least 1 MΩ when tested at 500 V. Then the stator is heated in the furnace, the grooves are cleaned, new coils are made to the specified dimensions and inserted into place. After varnishing and baking, the motor is reassembled and passes load control tests.

Rewinding is different from major repairs. If rewinding solves electrical problems, then major repairs eliminate mechanical ones: bearings are changed, the shaft is leveled, dynamic balancing is carried out. In reality, these two approaches are often combined to return the engine to full life. This combination is widely recognized within electric motor repair services, which focus on both electrical and mechanical restoration.

The result is obvious. In the hot climate of the UAE, rewinding is a strategy to save equipment and money. It reduces downtime, restores reliability, and provides a service life comparable to a new motor. In a world where every minute of downtime is expensive, rewinding is becoming the best alternative to replacement.

Fixie owner, dreamer, audiophile, hand letterer and fullstack designer. Performing at the junction of simplicity and elegance to develop visual solutions that inform and persuade. Concept is the foundation of everything else.